Services

Experts in track construction.

As an approved business for all line speeds, we work on the maintenance of tracks, rails, sleepers, ballast and formation. We therefore have a comprehensive fleet that allows us to operate several major construction sites simultaneously. Alongside six tamping machines and ballast ploughs, this also includes ballast cleaning, a formation rehabilitation machine and a renewal train. High-performance machines are the centrepiece of our work, which is why we have been relying on partners like Plasser & Theurer and Matisa since our founding.

We see ourselves as modern track constructors who ensure that trains and passengers arrive safely.

One-of-a-kind rail treatment.

Schweerbau is the only company in the world to employ all conventional rail treatment methods. The performance range includes grinding, milling, planing and rotational planing. We are the only company in Germany to grind in accordance with the BÜG (besonders überwachtes Gleis – specially monitored track) procedure, thereby ensuring quiet.

The aim of classic rail treatment is to eradicate faults from rails in tracks and points, and to optimise the running surface. Our decades of experience, investment in consistently modern machines and patented constructions make it possible to work in a way that saves both time and resources. For example, we invented a rotational plane that works without generating any dust or sparks – sounds interesting? It really is!

Mobility for Europeu2019s urban population.

Hamburg, Berlin, London, Paris. These cities rely on seamless urban transportation and underground railways play an essential part. We ensure that cities keep moving. The expert treatment and repair of rails in metros and trams is our contribution to a climate-friendly transport revolution. Here, our aim is to work in as environmentally and passenger-friendly a way as possible. To do this, we use specialist machinery and focus on low-emission engines, special filters and outstanding dust extraction. The next generation of machines that are battery-operated and work in tunnels without diesel emissions or dust are about to enter operation.

The construction classic.

Away from the rails, our civil engineering squad is at work. Our portfolio includes sewer construction, road building, developments and special projects (including rain retention basins, integration of special shaft structures, etc.). But the construction and improvement of plazas, pavements and bicycle paths is also an important aspect. With our work, we are helping to shape the urban landscape, and our clients include districts, towns and the German armed forces. Construction sites in populated (urban) areas in particular benefit from our time management and experience.

We also ensure the resource-friendly use of materials and machines in this area.

The fascinating world of sewer networks.

Sounds disgusting? Only sometimes. Ordinarily, of course, we get to work before any major incidents occur. The regular maintenance of rainwater and sewage systems is a crucial component of functional urban life. This includes sewer cleaning, sewer inspections and sewer leakage tests. We have the appropriate equipment, expertise and the necessary certification to meet the requirements of the ‘SüwV Kan’ legislation (statutory self-monitoring of sewer systems), for example, as well as the guidelines for new inspections.

Where sparks fly.

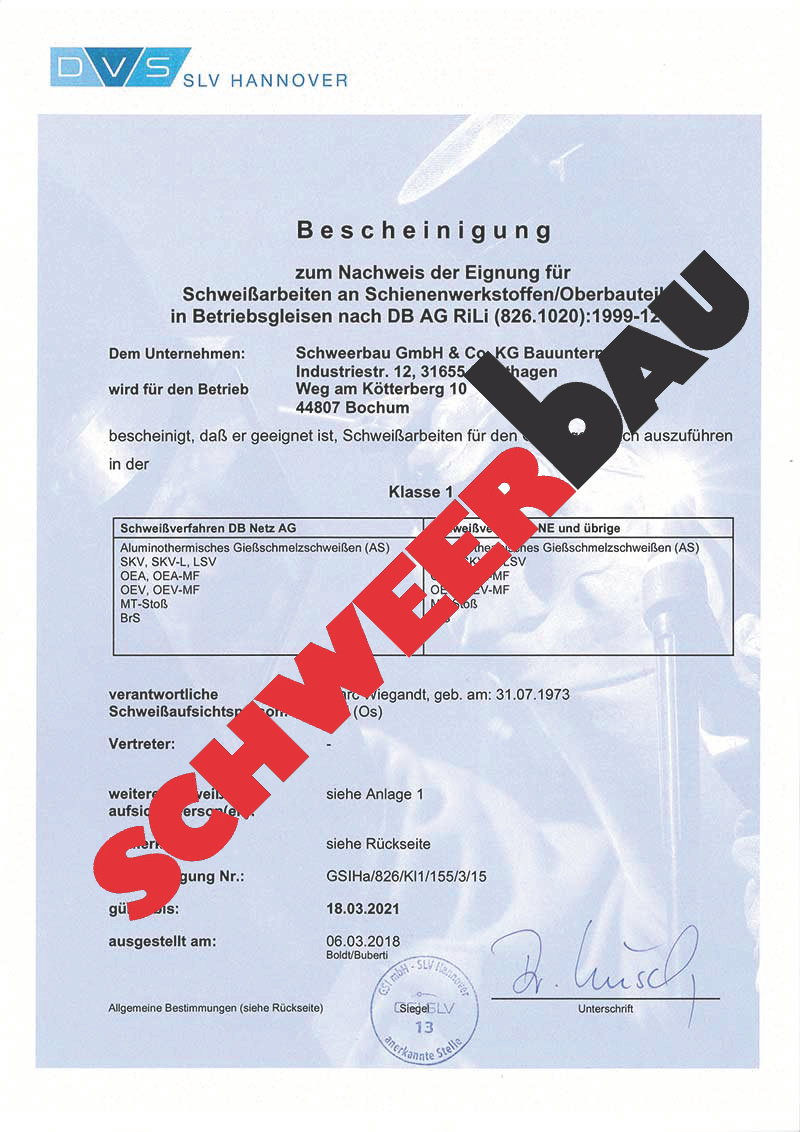

Welding technology is a daily component of our work and is used at almost all of our construction sites. Our service portfolio in the field of welding technology is therefore extensive, and includes:

- Superstructure joint welding

- Aluminothermic joint welding AS-SkV, AS-SkV-L, AS-LSV

- Arc joint welding

- Maintenance of rails and points with welding and grinding technology

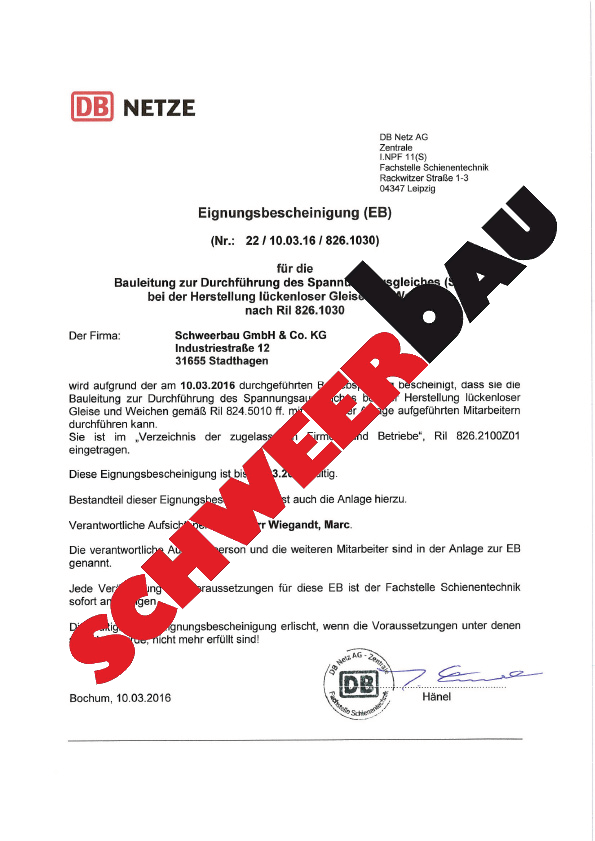

Documenting the proper execution of tension equalisation also forms part of our work

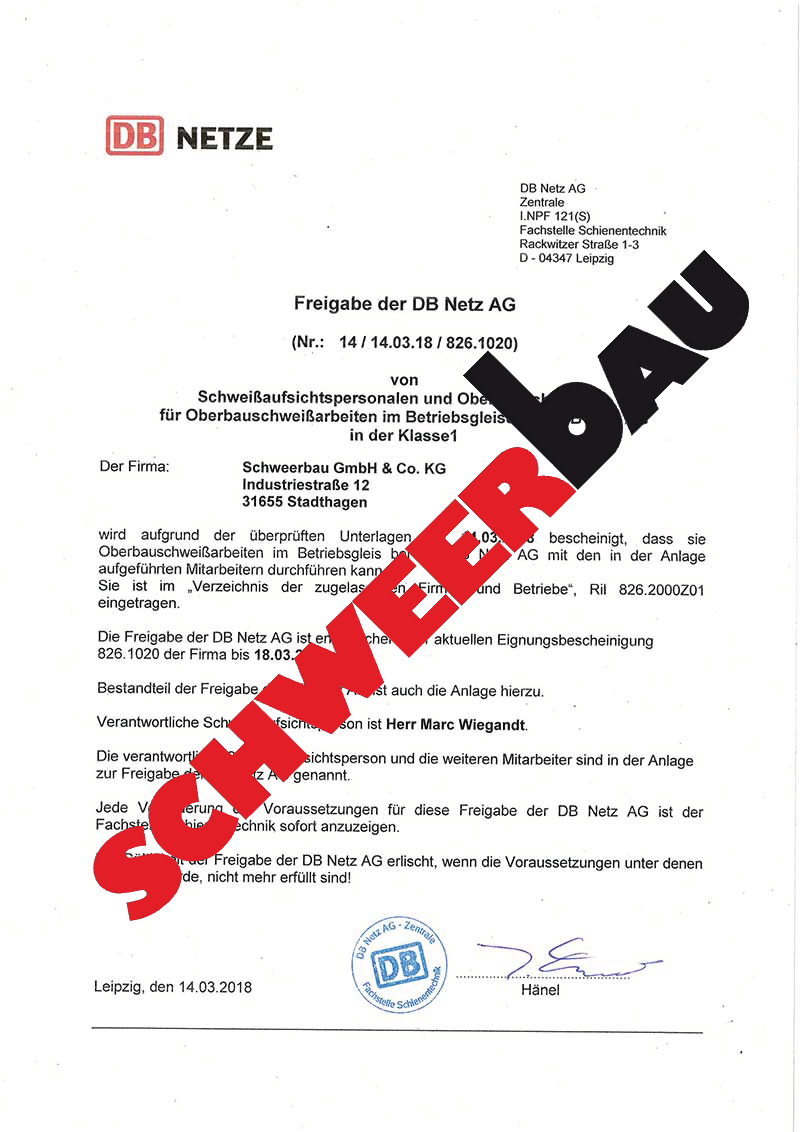

We conduct all welding work on rail materials and upper sections for operational tracks in accordance with

DB AG guideline 826.1020 in class 1.

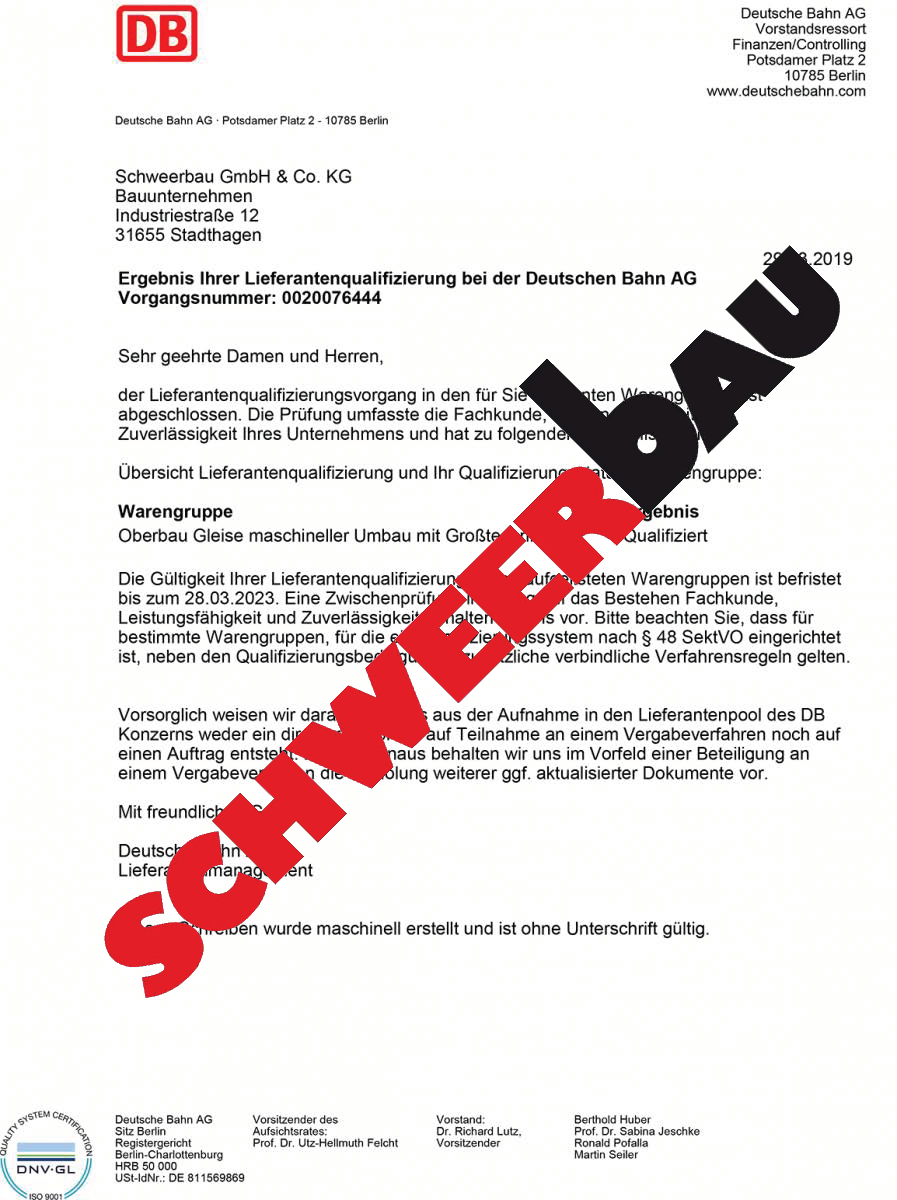

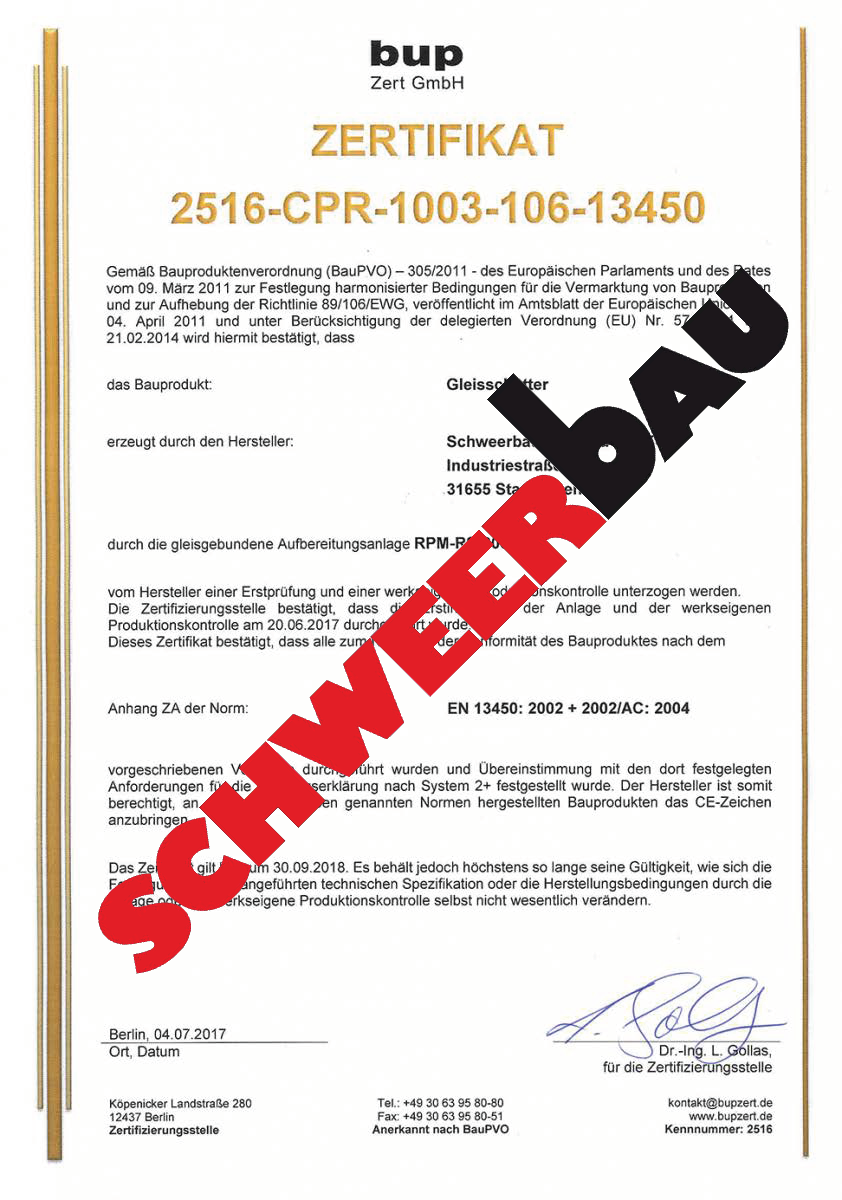

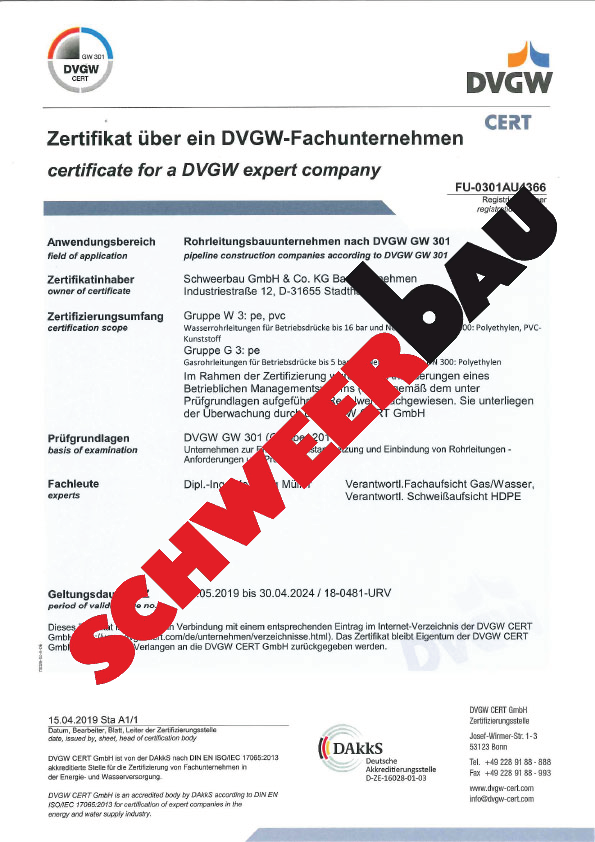

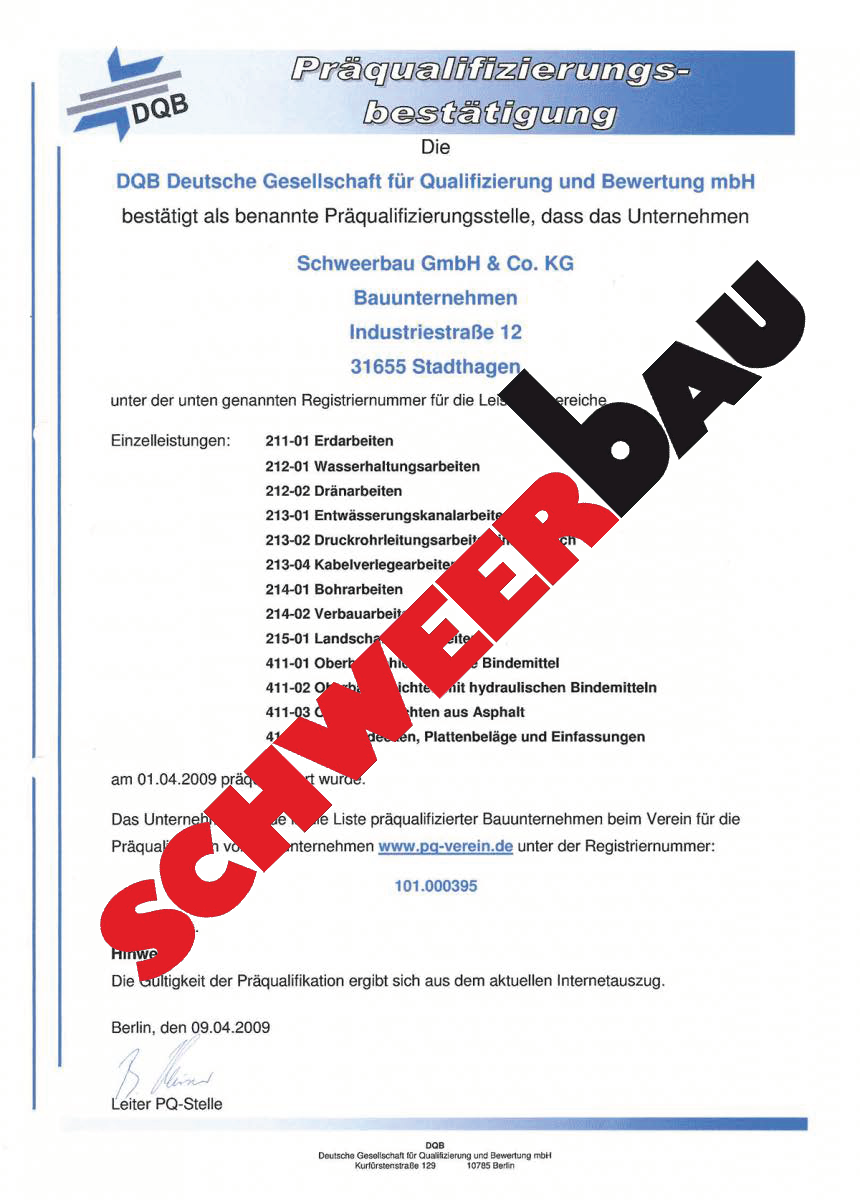

The current certificates can be found on our certificate page.

Mobility under high voltage

Since April 2022 we are qualified by the Deutsche Bahn to build and maintain the overhead contact line systems in the rail network. Behind the tangle of wires are intricate operations that require diligence and expertise, such as:

- Earth return bonding

- Mast construction

- Maintenance of catenary systems

- Return wiring

- Swiveling

By using our own working platforms, we can quickly reach the most remote areas. In this way, we ensure a reliable power supply to the Railroad power grid and contribute to safe commuting and environmentally friendly travel.

Patents and certificates

Innovation and proven trust.

We work on the best machines from renowned manufacturers, but also develop large equipment together with strong partners or improve what we already have.rnrnOver the years, we have implemented countless ideas and patented some of them. In the process, it is always about efficiency and working methods that are resource- and environmentally friendly.rnHere you will find a list of our certificates.

Download of all patents and certificates

These machines ensure mobility.

Click through our fleet. Join our team if you want to work on them and come along for the ride!

Download machines